B-906, Infinity Tower, Corporate Road, Prahladnagar, Prahlad Nagar, Ahmedabad, Gujarat - 380015

- GST NO. : 24AFJPP8347K1ZW

1 Ton (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler, Trader, Distributor |

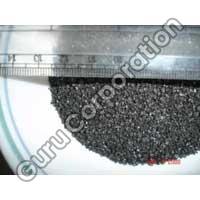

| Size | Powder |

| Model Number | 091 |

| Brand Name | GG+ ( Trademark TM ) |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Material

Powder

Application

Uses in LRF, Ladle, Furnace, VOD, AOD

SiO2 Content (%)

10-12%

Al2O3 Content (%)

88%

CaO Content (%)

2%

K2O Content (%)

0.1%

Place of Origin

India

Odaur

Grey

Product Code

091

Port

Mundra Gujarat India

Payment Terms

L/C, T/T, Other

Delivery Time

Within 1 Week

Packaging Details

This product available in 25 / 50Kg Plastic or Paper Bags.

Guru's GG+TM Fulotic FumicDe-Oxidizer cum Slag Conditioner has been well applied in SunFlag Steel Ltd, Panchmahal Steel Ltd, Rajputana Stainless Ltd, Mangalam Alloys Ltd, Virat Alloys, Shubhlaxmi Casting & many Foundries based steel plants in Bhavnagar, Baroda, Mumbai, Nagpur , Kutch, Gandhidham, Rajkot, Ankleshwar, surat, Tarapur, Punjab, Rajasthan etc.

The quality of a variety of billet/bloom/slab produced by the continuous casting machine with GG+TM Fulotic is far better due to almost zero transfer of Slag Rich In Alumina from ladle to tundish & the qualitative production ability (lesser Alumina Stringer/inclusions or nozzle clogging) of high grade special steel & alloys.

Steel is greatly increased with definite improvement in ladle life! Probability of early closure of ladle, thus wasting precious steel for fear of slag teeming is also reduced zero. Same material if used in the EAF or converter tapping minimizes slag tapping to less than 50kg/tapping, thus ensuring no blocking of EBT hole or oxide slag in the ladle otherwise needing high consumption of de-oxidizers.

Benefits used by GG+TM Fulotic of Guru Metachem Pvt.Ltd are: Improving the yield rate of liquid steel:- After using 5kg/1mt GG+ Fulotic, The recovery rate of molten steel increases 0.2% to 0.6%. Based on the theoretical calculation and customers? feedback, the yield rate of liquid Metal is improved. So energy is conserved, cost of production is reduced, profit is improved.Improving the cleanliness of liquid steel:- The main factor that affects the purity of manufactured steel lies in slag entering the tundish.

The using of GG+TM Fulotic reduces the quantity of slag to a minimum, so the steel purity is improved and the requirement of clean steel is met.

Avoiding the clogging of nozzle:- Slag entering the dish also attributes to the clogging of nozzle when the liquid steel is re-oxidized. The application of ladle slag detection system can reduce the happening of nozzle clogging.

The quality of a variety of billet/bloom/slab produced by the continuous casting machine with GG+TM Fulotic is far better due to almost zero transfer of Slag Rich In Alumina from ladle to tundish & the qualitative production ability (lesser Alumina Stringer/inclusions or nozzle clogging) of high grade special steel & alloys.

Steel is greatly increased with definite improvement in ladle life! Probability of early closure of ladle, thus wasting precious steel for fear of slag teeming is also reduced zero. Same material if used in the EAF or converter tapping minimizes slag tapping to less than 50kg/tapping, thus ensuring no blocking of EBT hole or oxide slag in the ladle otherwise needing high consumption of de-oxidizers.

Benefits used by GG+TM Fulotic of Guru Metachem Pvt.Ltd are: Improving the yield rate of liquid steel:- After using 5kg/1mt GG+ Fulotic, The recovery rate of molten steel increases 0.2% to 0.6%. Based on the theoretical calculation and customers? feedback, the yield rate of liquid Metal is improved. So energy is conserved, cost of production is reduced, profit is improved.Improving the cleanliness of liquid steel:- The main factor that affects the purity of manufactured steel lies in slag entering the tundish.

The using of GG+TM Fulotic reduces the quantity of slag to a minimum, so the steel purity is improved and the requirement of clean steel is met.

Avoiding the clogging of nozzle:- Slag entering the dish also attributes to the clogging of nozzle when the liquid steel is re-oxidized. The application of ladle slag detection system can reduce the happening of nozzle clogging.

Looking for "De Oxidizer GG Slag Conditioner" ?

Ton

Explore More Products